1. Owing to the various grades of material in the same metallic group, metals are not designated by name, but are marked to indicate clearly the specification with which they comply. Identification markings are usually made with metal dies, but where such a procedure may harm the material, stenciling or printing with paint enamel or ink is employed.

2. Standard Color Code: The markings described above may not be easily observed, so an additional method, known as the Standard Color Code, is employed to make identification more obvious. The appropriate identification colors for each specification are given in A.P. 1086 and in A.P. 1464 B. The colors are marked in bands across corners of sheets and around the ends of tubes and rods. Should it be necessary to cut o material from a marked sheet, tube or rod, the cutting should be done in such a manner that the identification colors remain on the material which is not required for use.

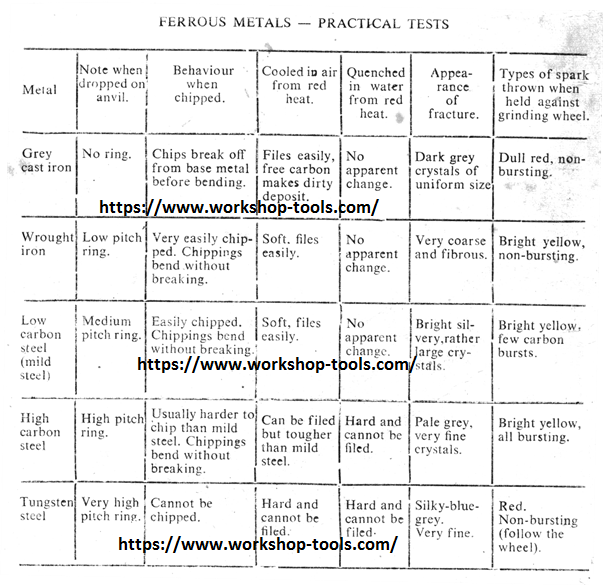

3. Practical Tests: The approximate identification of some of the more commonly known metals may be established by making the following tests, but such tests are unreliable and must not be employed when material to specification is required for use.

Test results of some of the popular metals are given below:

Aluminum: Tin white in color, light in weight, non-magnetic. soft, and bends easily. Application of caustic soda turns metal white.

Alclad: Differs from sheet aluminium by being springy and more resistant to bending; application of caustic soda turns the surface of the sheet white and the edge black.

Duralumin: Same properties as Alclad except that, the application of caustic soda turns surface black.

Magnesium Alloys: Tin white in color, very light, non-magnetic, easy to file and filings ignite in a flame; application of copper sulphate causes effervescence and the affected parts ‘turn black.

Solder: Tin white in color, very heavy and soft, non-magnetic, low melting point (ascertained by use of hot soldering iron); will mark white paper due to lead content and a crackling sound when bent indicates high tin content.

2. Standard Color Code: The markings described above may not be easily observed, so an additional method, known as the Standard Color Code, is employed to make identification more obvious. The appropriate identification colors for each specification are given in A.P. 1086 and in A.P. 1464 B. The colors are marked in bands across corners of sheets and around the ends of tubes and rods. Should it be necessary to cut o material from a marked sheet, tube or rod, the cutting should be done in such a manner that the identification colors remain on the material which is not required for use.

3. Practical Tests: The approximate identification of some of the more commonly known metals may be established by making the following tests, but such tests are unreliable and must not be employed when material to specification is required for use.

Test results of some of the popular metals are given below:

Aluminum: Tin white in color, light in weight, non-magnetic. soft, and bends easily. Application of caustic soda turns metal white.

Alclad: Differs from sheet aluminium by being springy and more resistant to bending; application of caustic soda turns the surface of the sheet white and the edge black.

Duralumin: Same properties as Alclad except that, the application of caustic soda turns surface black.

Magnesium Alloys: Tin white in color, very light, non-magnetic, easy to file and filings ignite in a flame; application of copper sulphate causes effervescence and the affected parts ‘turn black.

Solder: Tin white in color, very heavy and soft, non-magnetic, low melting point (ascertained by use of hot soldering iron); will mark white paper due to lead content and a crackling sound when bent indicates high tin content.

Comments

Post a Comment