Method of Heating

Steel should be heated slowly and uniformly, as the temperature to which steel is heated is one of the factors determining the success of any heat treatment. It is to use heating equipment which permits rigid control of the temperature. Muffle furnaces ovens usually heated by oil. gas or electricity, are clean to use, capable of high degree of heat and can be left at any given temperature Without fear of overheating.The use of the black smith's fire is not a good method of heating, as temperature control and uniform difficult to maintain. Unless great care is taken, the metal may become overheated and burnt.

When using a blacksmith’s fire heat the jobs, if possible, in a steel tube and not directly in the flame. Baths heated by oil or gas and containing low melting point alloys or molten salts provide a good method of heat-treating steel.

The heating is clean uniform and under strict control. Irregular shapes can be heated throughout without overheating. Various salts may be used in the bath according to the range of temperature required.

Measurement of Temperature

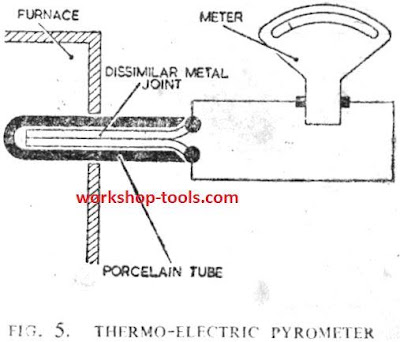

For measuring the temperature of bath, furnace or oven, some form of pyrometer is used.The “ Thermo-electric ” pyrometer embodies the “thermo-couple ” principle i.e. if two wires or the ends of strips of dissimilar metal are joined and the junction is heated, a small electrical pressure is generated.

With increase in temperature there is a corresponding increase in electric pressure. Connected to the free ends of the wires or strips, is a millivoltmeter, which has a scale calibrated to read degrees centigrade. The instrument is situated close to the heating apparatus.

The hot junction, protected by a porcelain tube, is located inside the furnace or bath.

When the open fire ‘method of heating is employed, the temperature of the work is judged by its temperature color, or if the temperature is within the normal tempering range, by color of the oxide film which forms on its surface.

Although the results obtained are satisfactory for forging operations, and the hardening and tempering of a single tool such as a cold chisel, the heat treatment of steel should be done by more accurate methods of measuring temperature.

Temperature and Approximate Color Guide

The colors and corresponding temperatures are given in the table set out below but it must be emphasized that experience is necessary to identify the colors accurately.Quenching

The usual quenching media in the order of rapidity of effect are brine, water, oil and air. Work which is to be hardened all over should be plunged straight“ into the quenching medium. If the work has to be partially quenched, it is advisable to move it, up and down to prevent the formation of a sharp hardening line which might subsequently be the cause of a crack. If the shape of the Work is irregular, quench the larger portion first. Cracks and distortion during quenching are often due to internal strains set up by previous forging, bending or other cold working, which can be avoided by normalizing prior to hardening.Successful hardening of steel will largely depend upon the following factors :

a) Control over the rate of heating specially to prevent cracking of thick and irregular sections.

(b) Thorough and uniform heating to the correct hardening temperature.

(c) Correct heat absorbing capacity, viscosity and temperature of quenching media.

Tempering Temperatures

The higher the tempering temperature, the lesser the hardness. but the greater the toughness of the steel. Thus the purpose of the tool or component must be considered. The tempering temperature may be approximately determined by the “temper color" appears on the bright surface of steel when slowly heated. Each color corresponds to a particular temperature.“ One heat” Method of Hardening and’ Tempering

9. This is the method used for tools which require a hard point or cutting edge with the remainder of the tool left tough to Withstand hammering or shock, e.g., cold a chisels, center punches etc. The procedure for making, hardening and tempering a carbon“ steel chisel by this method is as follows :Heat the metal to a light cherry red color and forge it to shape.

- Normalize and when cold, grind roughly to shape.

- Heat the cutting end half of the chisel to cherry red, then plunge vertically into water to about a quarter of the length, moving it up and down a little to prevent a sharp line between the quenched and unquenched portions which would cause “water line” cracks.

- When the point of the chisel is black, withdraw it from the water, polish the point with emery‘ or sand stone and observe the temper colors formed as the heat flows down from the unquenched portion.

- When the desired color (purple brown) appears, instantly quench the tip, and wait until all visible red heat has died away, before submerging the remainder of the tool. Grind the cutting edge, exercising care not to overheat the stool.

Annealing Temperatures

10) The temperature for annealing should be above the upper critical point for steel containing upto 0-87% Of carbon and below this point for steels containing a higher percentage of carbon. For annealing single item by the Smith’s fire method the item should be heated to a cherry red and allowed to cool as slowly as possible with, the "fire" or in hot ashes and must be excluded from draughts.

Thanks for sharing the best information and suggestions, If you are looking for the best stainless steel stub end, then Rajtilak Metal. Highly energetic blog, I’d love to find out some additional information.

ReplyDeleteYour blog is awfully appealing. I am contented with your post. I regularly read your blog and its very helpful. If you are looking for the best Duplex Steel fittings, then visit Great Metal. Thanks! I enjoyed this blog post.

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteThanks for sharing the best information and suggestions, I love your content, and they are very nice and very useful to us. If you are looking for the best Stainless Steel Pipe manufacturer,then Oshwin Overseas.I appreciate the work you have put into this.

ReplyDeleteReally helpful down to the ground, happy to read such a useful post. I got a lot of information through it and I will surely keep it in my mind. Keep sharing. If you are looking for some useful data and information regarding e250 plate then visit STANCOR ALLOYS INC.

ReplyDeleteAfter going through your contents I realize that this is the best of my knowledge as it provides the best information and suggestions. This is very helpful and share worthy. If you are looking for the best A193 B6 Bolts then visit VIHA STEEL & FORGING. Keep sharing more.

ReplyDeleteThanks for such a pleasant post. This post loaded with lots of useful information. Keep it up. If you are looking for the best information and suggestions related to a193 b16 then visit fastenersonline.

ReplyDeleteYour contents are completely awesome and share worthy. I really appreciate your efforts that you put on this. Keep sharing. For more Inconel 600 Bolts related information visit Raaj Sagar Steels

ReplyDeleteThis information is meaningful and magnificent which you have shared here. I am impressed by the details that you have shared in this post and it reveals how nicely you understand this subject. You can also visit duplex pipe manufacturer for more Perfect Impex related information. I would like to thanks for sharing this article here.

ReplyDeleteI liked the way you wrote on heat treatment. You did not divert from the topic even once which I have not seen in many other writers.Also the subject knowledge is appreciable.

ReplyDeletecalifornia metal fabricators

I wanted to thank you for this great Information and knowledge, I definitely loved every little bit of it. I have you bookmarked your web site to check out the latest stuff you post. Your blog is eye-catching. I get pleasure from it. Thanks for sharing this beautiful piece of writing with me, get more information at Stainless Steel 316L Bolts for more Jignesh Steel related information and knowledge.

ReplyDelete