Corrosion is the conversion of metals to metallic oxides and salts which neither resemble nor possess the physical properties of the base metals. The conditions under which corrosion may occur are many and varied, but it can be stated that the cause is due to electro-chemical action.

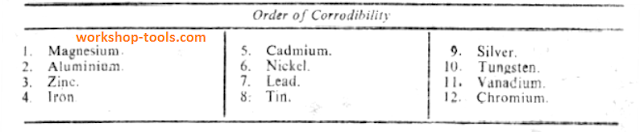

Some metals have a greater tendency to corrode than others. The following table shows various metals in their order of corrodibility.

Surface corrosion is caused in a mild form by normal atmospheric conditions, becoming more pronounced in a moist atmosphere, even more rapid with alternate moist and dry conditions and greatly accelerated by high temperature.

As the corrosion reduces the thickness of the base metal it weakens the structure; the surface finish is also roughened. If the thickness of metal has not been reduced below the limit of size, the corrosion may be removed and suitable protective treatment applied.

If the corrosion has penetrated to a depth whereby the part is below the limit of size or has caused pitting, the corroded part must be renewed.

When in contact, dissimilar metals such as steel and duralumin or the same metal in different heat treated states, for example annealed and normalized duralumin, readily corrode due to moisture and electrolytic action.

Therefore joining of dissimilar metals is not advisable, but where this is unavoidable. special protective compound must be spread over the contacting surfaces before assembly.

Intercrystaline corrosion is caused by action between the elements in some alloys, or may be caused by incorrect heat treatment; light alloys and stainless steel are susceptible to this kind of corrosion. The presence of intercrystalline corrosion in aircraft parts is very rare, but if detected the affected part must be renewed; once started, this type of corrosion is impossible to check. '

Some metals have a greater tendency to corrode than others. The following table shows various metals in their order of corrodibility.

Surface Corrosion

This is the most common form of corrosion, but is readily detected by the difference in appearance between the products of corrosion and base metal. Corrosion on steel (commonly known as rust) is reddish-brown in color; on aluminium‘ and its alloys it is a white or grey powder and on copper a greenish discoloration.Surface corrosion is caused in a mild form by normal atmospheric conditions, becoming more pronounced in a moist atmosphere, even more rapid with alternate moist and dry conditions and greatly accelerated by high temperature.

As the corrosion reduces the thickness of the base metal it weakens the structure; the surface finish is also roughened. If the thickness of metal has not been reduced below the limit of size, the corrosion may be removed and suitable protective treatment applied.

If the corrosion has penetrated to a depth whereby the part is below the limit of size or has caused pitting, the corroded part must be renewed.

Corrosion due to Galvanic Action

This form of corrosion is similar in appearance to surface corrosion, but is caused by metals widely separated in the order of corrodibility, being in contact with each others.When in contact, dissimilar metals such as steel and duralumin or the same metal in different heat treated states, for example annealed and normalized duralumin, readily corrode due to moisture and electrolytic action.

Therefore joining of dissimilar metals is not advisable, but where this is unavoidable. special protective compound must be spread over the contacting surfaces before assembly.

Inter-crystalline Corrosion

This type of corrosion is very difficult to detect, as no corrosion products are visible. It occurs in alloys, along the crystal boundaries, in the form of cracks, which may only be visible under a magnifying glass.Intercrystaline corrosion is caused by action between the elements in some alloys, or may be caused by incorrect heat treatment; light alloys and stainless steel are susceptible to this kind of corrosion. The presence of intercrystalline corrosion in aircraft parts is very rare, but if detected the affected part must be renewed; once started, this type of corrosion is impossible to check. '

Comments

Post a Comment